1983

RPL 1N

The first semi-carried tomato harvester with collection bar “patented by CRF”

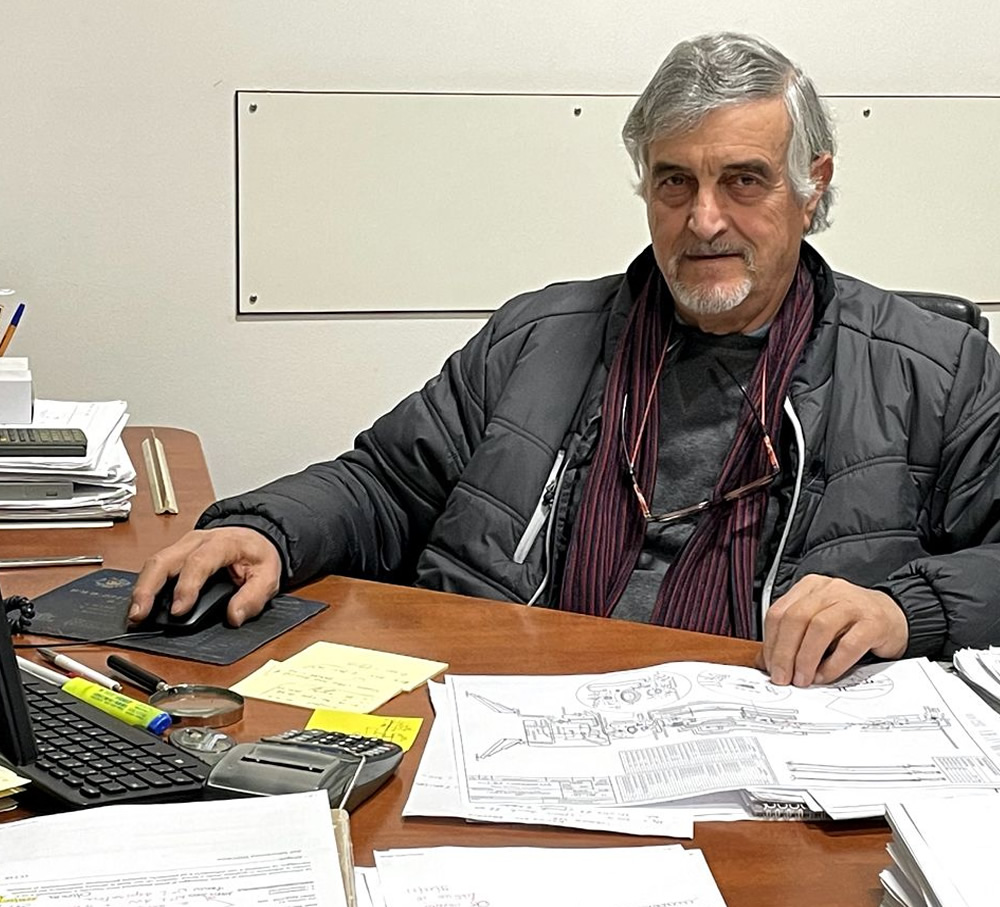

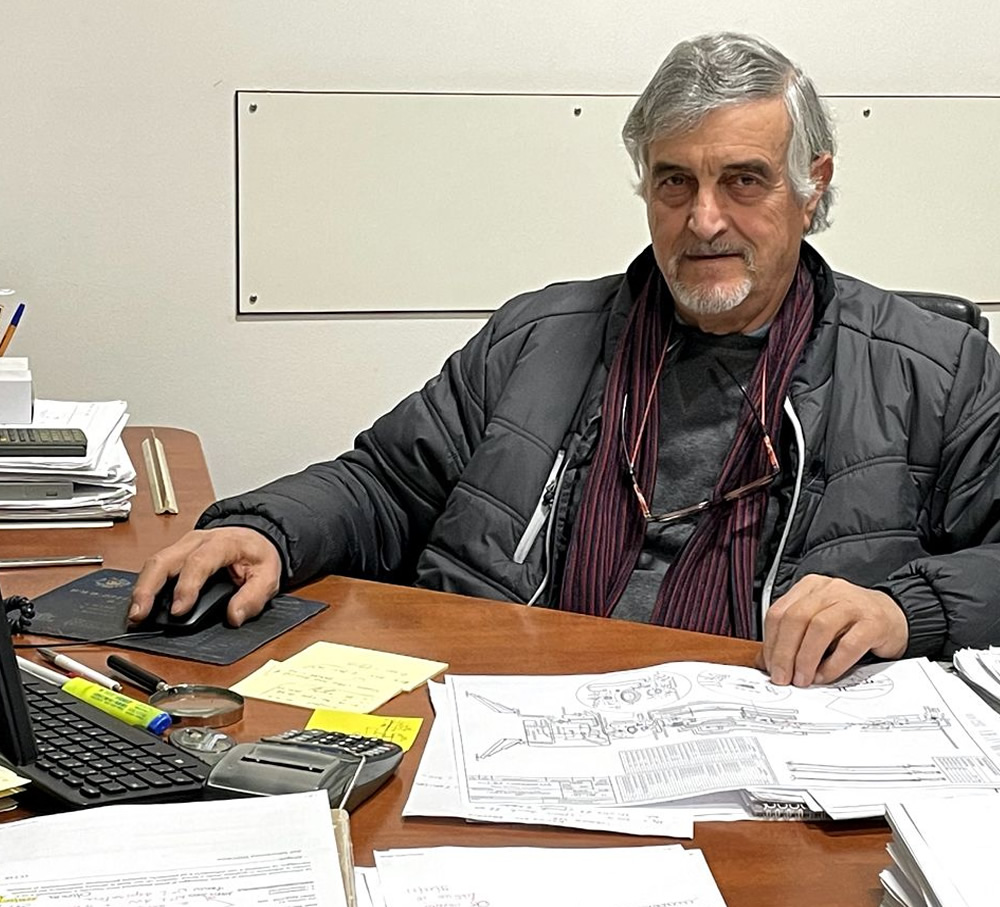

Sedulio Seri founded the company in 1983.

CRF produces the first tomato prototype picker in 1984.

In the same year, the founder Sedulio Seri, realizes and patents the innovative “Harvesting system with articulated elements”, also defined as “collection bar“, which drastically improves the pickers’ working: the exceptionality of such idea is strengthened by the fact that today, on all the modern pickers, is still present this system.

In the early 2000, the eldest son Andrea joins the company and the generational collaboration between father and son, immediately represent an added value to the company.

The company phylosophy reflects the tenacious character and the creative thinking of his founder: stubbornness, professionalism and an innate brilli ance, the gifts of a great entrepreneur, a great man, my father.

Graduated in mechanical engineering , he join the company in the early 2000.

The synergy created by the meeting of long-standing experience, expertise and knowledge with ideas brought by younger minds gives an important imput to CRF’s corporate growth.

Thanks to the continuous use of resources in the development and planning of new systems, and thanks to the special skills of our technical staff, the company is launching into the market high quality and innovative products.

All CRF machines are practical and easy to use: professional and techologically advanced

have thought for a simple approach and above all an easy management both for the big agricultural companies and the small farmers.

An ambitious project requires experience, sacrifice, vision and a lot of passion.

“An entrepreneur is a person who sees something and has a desire to create it”

by David Karp

Sedulio Seri founded the company in 1983.

CRF produces the first tomato prototype picker in 1984.

IIn the same year, the founder Sedulio Seri, realizes and patents the innovative “Harvesting system with articulated elements”, also defined as “collection bar“, which drastically improves the pickers’ working: the exceptionality of such idea is strengthened by the fact that today, on all the modern pickers, is still present this system.

In the early 2000, the eldest son Andrea joins the company and the generational collaboration between father and son, immediately represent an added value to the company.

The company phylosophy reflects the tenacious character and the creative thinking of his founder: stubbornness, professionalism and an innate brilli ance, the gifts of a great entrepreneur, a great man, my father.

Graduated in mechanical engineering , he join the company in the early 2000.

The synergy created by the meeting of long-standing experience, expertise and knowledge with ideas brought by younger minds gives an important imput to CRF’s corporate growth.

Thanks to the continuous use of resources in the development and planning of new systems, and thanks to the special skills of our technical staff, the company is launching into the market high quality and innovative products.

All CRF machines are practical and easy to use: professional and techologically advanced

have thought for a simple approach and above all an easy management both for the big agricultural companies and the small farmers.

An ambitious project requires experience, sacrifice, vision and a lot of passion.

"An entrepreneur is a person who sees something and has a desire to create it"

by David Karp

One of CRF’s priorities is welcoming customers, whether when they visit our office or when they contact us by phone or email.

Courtesy, clarity and competence are some of the elements that characterize the service provided by our receptionists

The first semi-carried tomato harvester with collection bar “patented by CRF”

The first self-propelled tomato harvester with spring shaker system

The first self-propelled tomato harvester with lateral collection bar

The first series with lateral collection bar and variable track width

A great innovation: the first belt shaker system. A few years later, CRF applies the first electronic sorter Odenberg to discard impurities.

A revolution: the first tomato self propelled lateral harvester with belt shaker system, variable track width, first electronic sorter Odenberg and lateral and longitudinal leveling.

To increase the hourly production capacity and follow market trends, the first harvester with rotating shaker system with vibrating spikes.

The first model of vibrating shaker made by CRF for olive harvesting, with control wire.

Self-propelled lateral harvester for super intensive plants

The first hydraulic self propelled repotting machine on the world for quick potting process of the seedling in land area or greenhouse

The first grape harvester in the world applied to tractor, ideal for harvesting grapes in difficult situations

The latest and most sophisticated self-propelled tomato harvester with 4 traction wheels drive steering, variable track width, air-conditioned cab, rotating shaker system , rear Vine Cutter system and manual sorting station with hydraulic movement.

Facilitator trailer for field harvesting of vegetables for industry and fresh market, respectively.

The first semi-carried tomato harvester with collection bar “patented by CRF”

The first self-propelled tomato harvester with spring shaker system

The first self-propelled tomato harvester with lateral collection bar

The first series with lateral collection bar and variable track width

A great innovation: the first belt shaker system. A few years later, CRF applies the first electronic sorter Odenberg to discard impurities.

A revolution: the first tomato self propelled lateral harvester with belt shaker system, variable track width, first electronic sorter Odenberg and lateral and longitudinal leveling.

To increase the hourly production capacity and follow market trends, the first harvester with rotating shaker system with vibrating spikes.

The first model of vibrating shaker made by CRF for olive harvesting, with control wire.

Self-propelled lateral harvester for super intensive plants

The first hydraulic self propelled repotting machine on the world for quick potting process of the seedling in land area or greenhouse

The first grape harvester in the world applied to tractor, ideal for harvesting grapes in difficult situations

The latest and most sophisticated self-propelled tomato harvester with 4 traction wheels drive steering, variable track width, air-conditioned cab, rotating shaker system , rear Vine Cutter system and manual sorting station with hydraulic movement.

Facilitator trailer for field harvesting of vegetables for industry and fresh market, respectively.

© CRF Costruzioni S.r.l. | P.IVA: 01042680536 | Privacy Policy | Cookie | CREDITS