DISCOVER THE BENEFITS

RPL 2017 N45

Represents the new concept of CRF tomato harvesters: its characteristics are lightness, agility, sturdiness and power at the same time.

Realized to harvest even in the most difficult conditions, it does not fear damp, argillaceous and wet grounds.

The big productivity and its remarkable collection speed, the game points of this harvester.

You can choose:

- Kit SMART 4.0 (Interconction)

- Air-conditioned cab

- MOT system

- Eear Vine Cutter system

- 4 traction steering wheels

FIND OUT HOW IT’S DONE

- RPL 2017 N45, basic model with standard equipment

- RPL 2017 N45 CAB, with air-conditioned cabin: tempered glass anti-solar radiation, pneumatic seat equipped with multi-function armrest and additional work lights

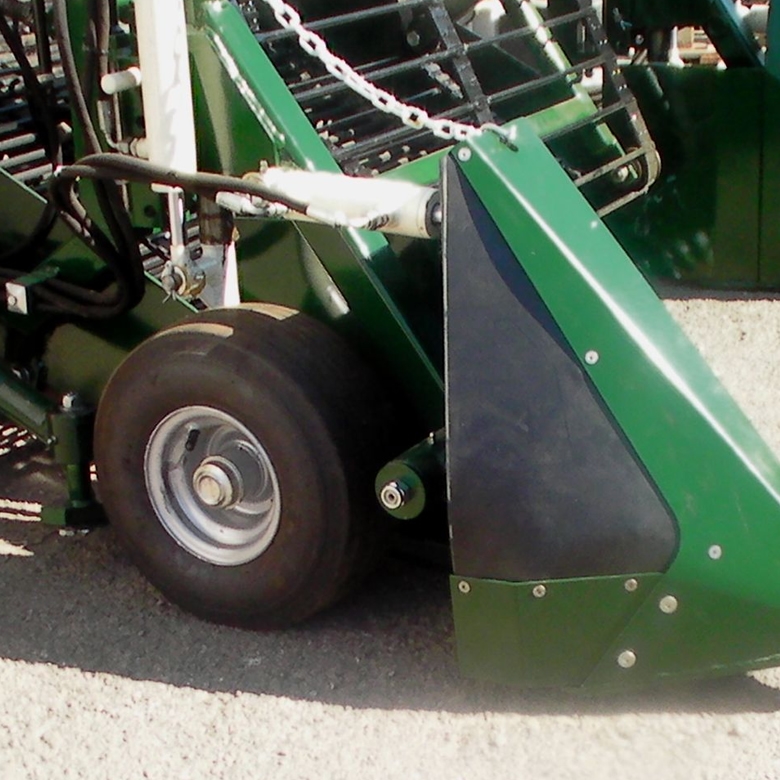

- RPL 2017 N45 4RS, steering wheels with selectable steering in three modes: 2 steering wheels, 4 steered wheels in counterphase, 4 steering in phase (shrimp)

- RPL 2017 N45 4RS CAB, the top class model, with air-conditioned cabin and 4 steering wheels

- Rotating shaker system with vibrating spikes

- 10 belt shaker system

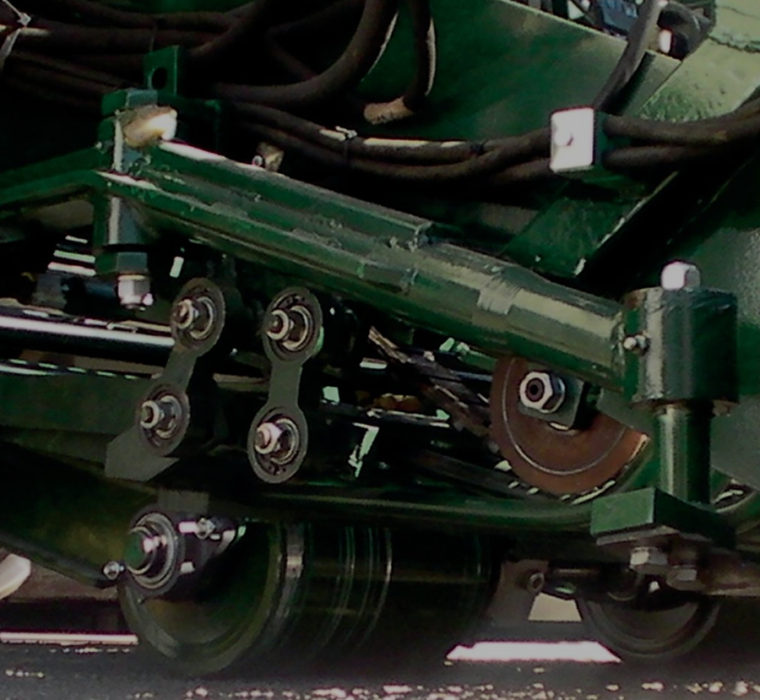

The collection head is equipped with 2 new sets of lifting fingers of steel which, during their alternate movement, vibrate and reduce the earth slope. The knife cut speed can changed. The Superior crop elevator conveyor belt makes easier the plant slope without damaging the product in any way, fitting its height.

The collection head (width 1,20 / 1,10 / 1,30 m), provided with new tips variables in inclination and height, allows the picker to pick up high quantities of tomato at a high collection speed without falling product.

By request, you can have a motorized roller on the right tip.

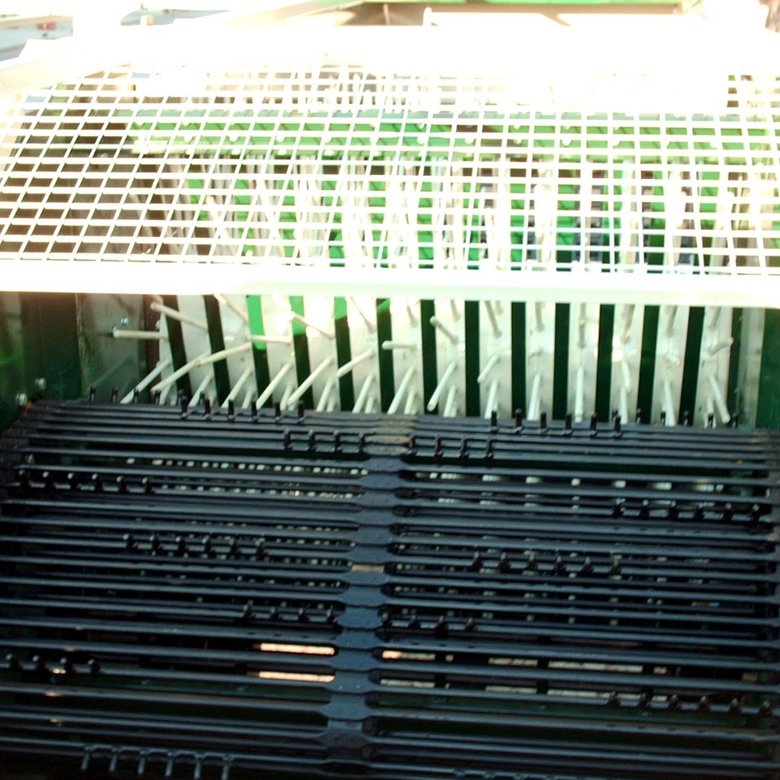

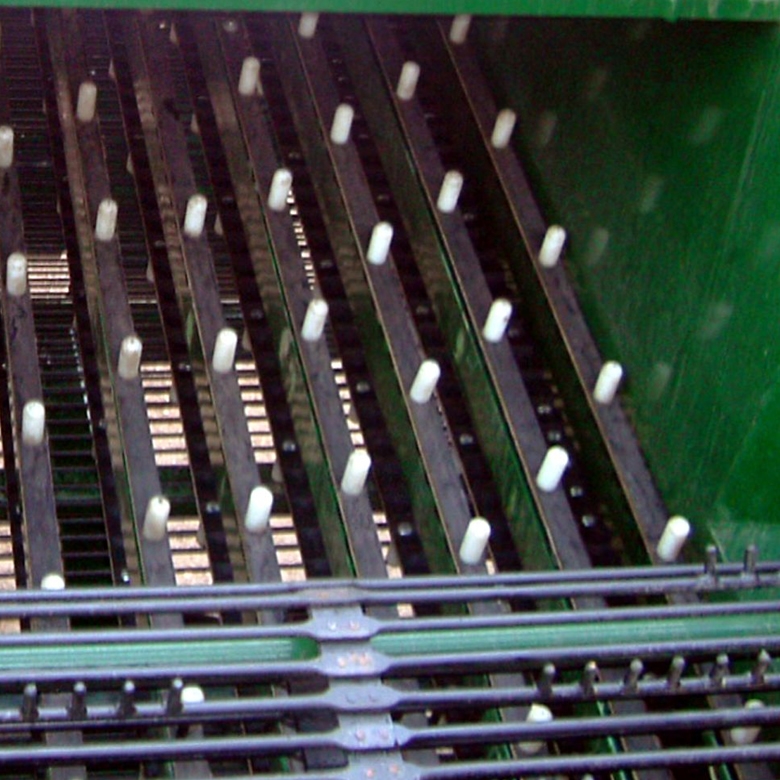

The rotating shaker system with vibrating spikes is formed by an cilinder rotor with rigid and radial spikes. The operator can regulate only the frequency and the speed of the vibration to determine the detachment of the gathered product. The system expects the use of a single toothed belt.

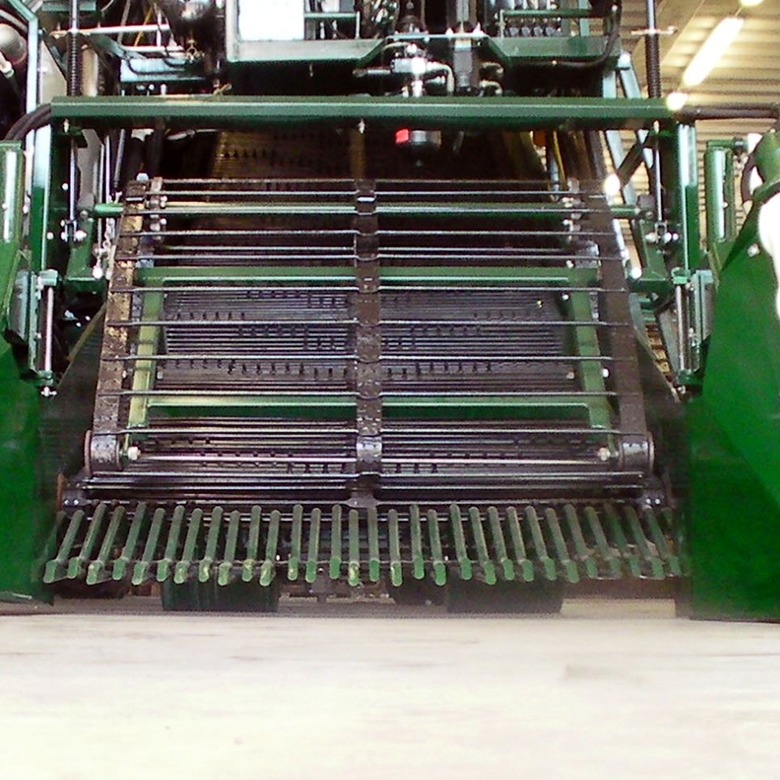

The system is composed of 10 belts, provided with plastic fingers, positioned the one at 15 cm from the other one to allow the tomatoes to fall with easiness on the below internal conveyor belt. Two potentiometers allow the operator to find the correct relationship between frequency and stroke of the belts to execute the delicate detachment operation with every type of tomato, round and long. This system allows high productions also with peeled tomato, ensuring the maximum quality of the gathered product.

For better crop cleaning, the fan has been upgraded and equipped with a double impeller: lighter impurities are expelled by the high airflow generated by the double rotor. With the Straw-Cutting system (optional), it pushes the plants toward the chopper knives for a better cut.

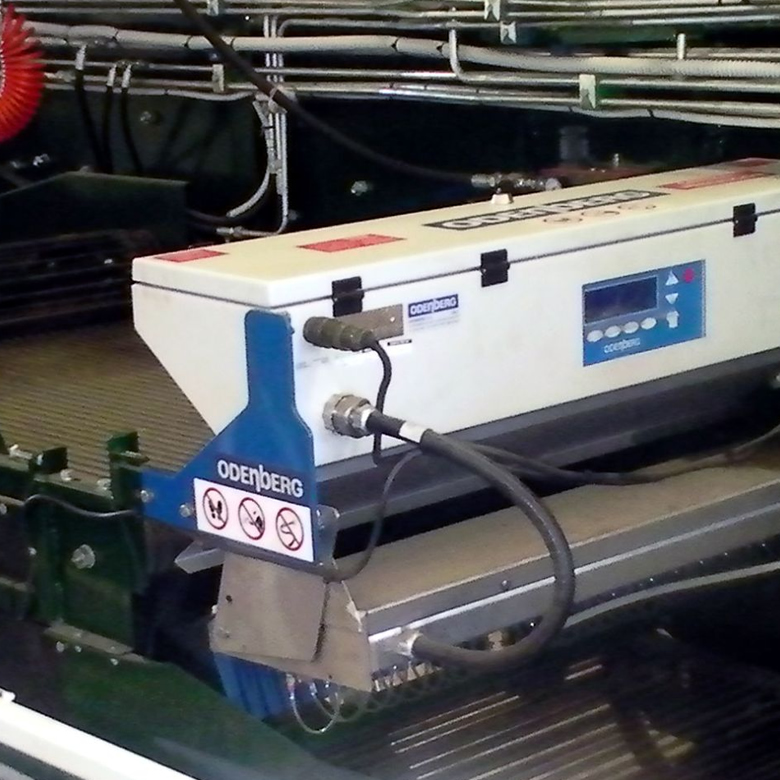

The 40-channel electronic sorter Tomra Odenberg can be programmed to reject stones, soil clods, impurities and also green tomatoes. The electronic sorter selects the tomatoes not just using the color but also using infra red sensing to determine the ripeness. The operator can change the selection parameters also by the control panel fixed on driver’s platform. Since the picker is leveling transversely and longitudinally, the product uniformly distributes himself on the long rubber conveyor for a perfect selection also in presence of high slopes.

During the picking up, the manual grading conveyor moves along to distribute more uniformly the tomatoes on the unloading conveyor. The wide and along unloading arm divided into two sections, allows an easy unloading of the tomatoes picked up both in trailers provided with bins, in tank trailers or directly on the tracks.

OPTIONAL

SEE HOW IT WORKS