The SMART 4.0 kit, developed by CRF, is an advanced interconnection system for the telematics transmission of performance, production, and faults in the machine-enterprise system.

The system includes:

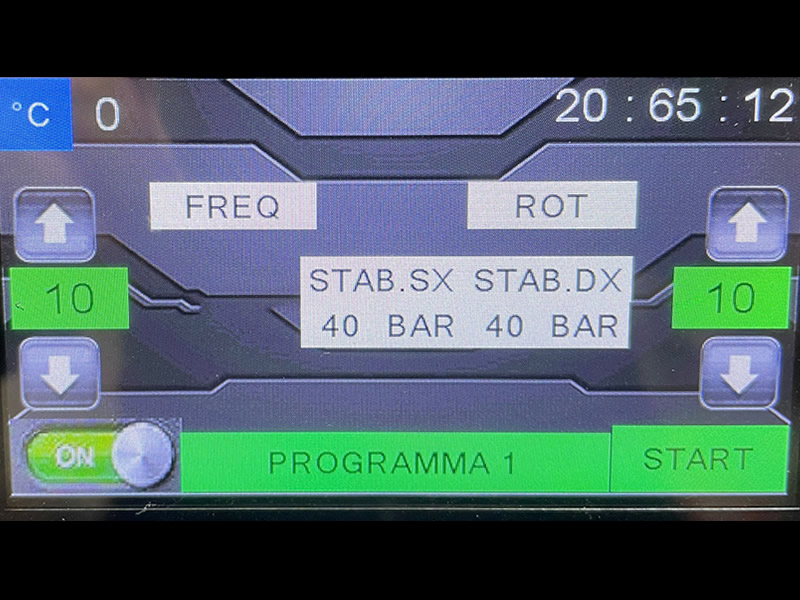

- A control panel with a touchscreen display,

- A PLC,

- A GSM card with a data SIM,

- A set of sensors for continuous monitoring of process and actuation parameters.

Data communication is two-way: during harvesting, the operating machine sends work data to the IoT platform, while from the app, parameters and programs can be configured and/or changed at any time with a simple click via smartphone, tablet, or PC.

The operator onboard the machine can also set and/or modify these parameters using the touchscreen display, which features a simple and intuitive graphical interface.

This remote control system allows for the optimization of machine settings, monitoring of working conditions and process parameters, and management of data. The data can be stored, archived, and exported in graphical or tabular format in various formats.

Currently, CRF has applied this technology to the following products:

- Grape harvester model VP10 – VP16

- Olive harvester model OLIVE ONE e OLIVE ONE TRACKED

- Vegetable facilitator trailer model CARO F

- Vegetable facilitator trailer model CARO I

This system can also be implemented on the new tomato harvester scheduled for production in 2025.