The SMART 4.0 kit for the VP10 harvester enables machine interconnection with the company via remote control and bidirectional data transmission. It includes a 7″ touchscreen dashboard, PLC, GSM module with antenna and SIM, and sensors for process data monitoring. The operator can select from two operating programs, even remotely.

For more details, see the page INDUSTRIA 4.0.

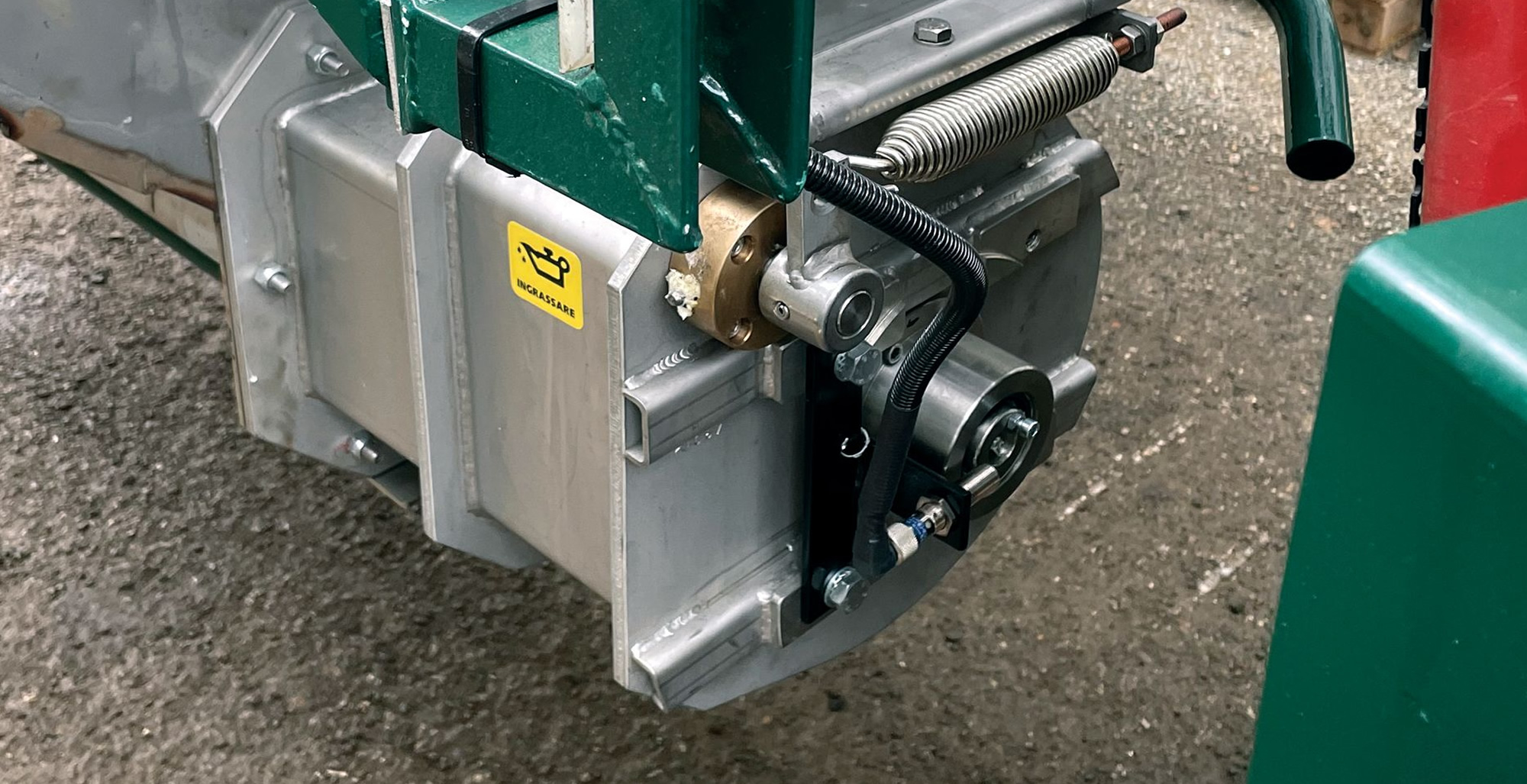

VP10 OPTIONAL