DISCOVER THE BENEFITS

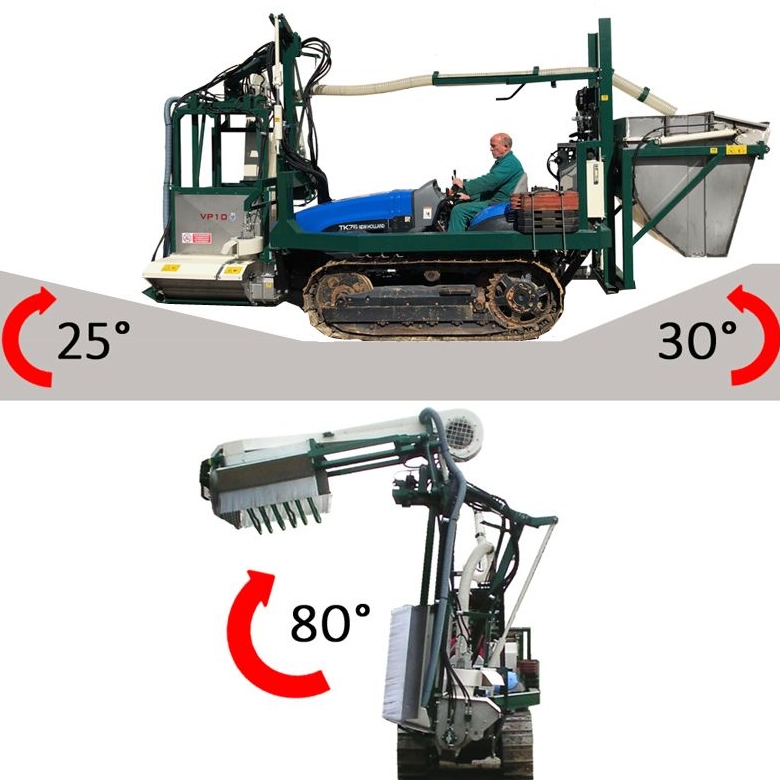

The VP10 is the world’s first vineyard harvester mounted on a tractor as an attachment, with the pendulum collection tunnel installed at the front and the grape collection tank at the rear. Its unique design allows to harvest in extreme conditions, previously considered unimaginable:

• old vineyards

• concrete posts, pre-stressed or perforated

• drop

• terraces

• narrow vineyard ends

• high lateral and longitudinal slopes

• upright vine

DISCOVER THE MODELS

VP10

You can choose between 2 models that differ in the size of the collection tank:

- VP10 with a 1000 kg capacity

- VP16 with a 1600 kg capacity

The VP10 is more suitable for challenging conditions with lateral or longitudinal slopes and narrow headlands, while the VP16 is ideal for long rows and high production volumes.

DETTAILS

The threshing unit is pendular, allowing it to self-guide along the row and facilitate the harvesting operations. Additionally, this system enables harvesting with concrete posts, even perforated ones, without…

Read more

…damaging them, as the pendulum “absorbs” some of the vibrations produced by the shaker unit.

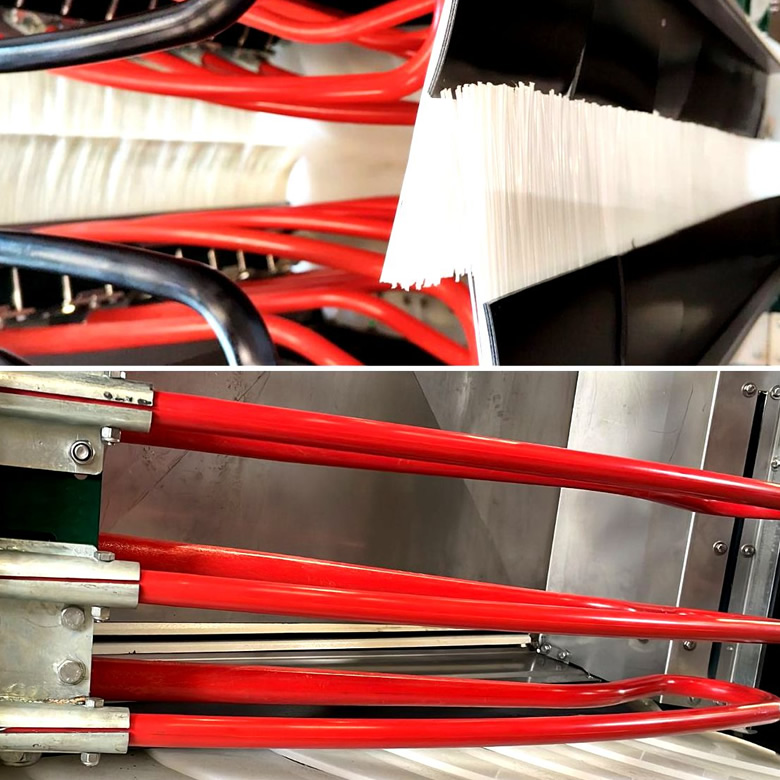

The harvesting system, consisting of two opposing series of curved horizontal shakers made of soft plastic material, enables rapid harvesting even with perforated concrete posts, without damaging them or causing…

Read more

…injury to the vines. The shaking speed and the distance between the shakers are adjustable to adapt to the row shape, the difficulty of grape detachment, and the size of the posts.

The powerful fan and its corresponding multi-jet air duct facilitate the transfer of the product onto the mobile grilles towards the auger, preventing grape loss to the ground while also ensuring better expulsion of leaves and impurities.

The harvested product is transported from the collection unit to the rear bin via a screw-pump-tube system. The screw rotation speed is adjustable based on the amount of product harvested and the forward speed. In case of blockage…

Read more

…from foreign objects, a device simultaneously stops the screw and the shaker to prevent product accumulation and loss. Additionally, to facilitate obstruction removal, the direction of the screw’s rotation can be reversed.

For emptying the tank, with automatic lifting of the transport tube, the operator can choose between two modes: exit the row and unload directly into the trailer (STANDARD OPERATION), or remain stationary along the row…

Read more

…and unload the harvested product into an additional bin carried by a second tractor (EXCLUSIVE OPERATION of VP10). The latter is especially useful for long or sloping rows, reducing movement time and avoiding dangerous unloading maneuvers.

The collection tunnel, which can be opened up to 80°, allows for quick maneuvers at the headlands, facilitating entry and exit from the row for unloading and overcoming obstacles along the row. Additionally, the 30° rotation…

Read more

…of the collection unit and the ability to lift the rear bin up to 3 meters enable access to rows with narrow headlands of just 3.5 meters.

On the right side of the driver’s seat, in an ergonomic position, there is an armrest with a multifunction electric joystick, allowing the operator to perform all operations of the threshing unit without removing their hand from the handle.

To prevent oxidation of white grapes on hot days, CRF offers a free kit consisting of 2 brackets for securing a liquid nitrogen or CO2 cylinder and a special connector for the pump, allowing the low-pressure injection of the antioxidant product.

The VP10 harvester is designed for quick mounting on a tractor using a universal supporting frame with 4 anchoring arms (2 front and 2 rear). To facilitate installation and removal, the front frame rests on adjustable supports, while…

Read more

…the rear part opens like a book with swiveling wheel supports, allowing easy entry and exit for the tractor.

OPTIONAL

SEE HOW IT WORKS