DISCOVER THE BENEFITS

The vibrating harvester, fixed on the rear of the tractor, is equipped with a patented harvesting head, a telescopic articulated arm, proportional electro-hydraulic movements and radio remote control.

Due to its features, it can be used for the harvesting of:

- Large olives

- Medium-small olives

- Narrow planting rows (even 4 meters between rows)

- Unpruned or heavily branched trees

- Early harvesting for high-quality oil

- Olives with difficult detachment

When paired with a second tractor, featuring the front Net Roller machine and the rear Aspirator, only a second operator is needed to complete the harvesting operation.

Possible incentives:

– TAX CREDIT with the SMART 4.0 kit

– NEW SABATINI (interest rate discount)

– CSR New operational plans for rural development

DISCOVER THE MODELS

You can choose between two models:

OLIVE ONE

OLIVE ONE SMALL

The second version, slightly more compact than the first, stands out for its design with a single telescopic extension and a turntable equipped with a worm screw and stop.

- Patented harvesting comb: Featuring 3 adjustable settings and ultra-flexible silicone teeth, ensuring highly effective harvesting without damaging the plant

- Proportional electro-hydraulic distributor: Ensures smooth movements of the articulated arm, improving both precision and speed during operation

- Turntable with worm screw: Allows easy operation even on steep slopes, adapting to various ground conditions

- Radio remote control: Provides optimal machine management, offering excellent visibility during harvesting, even in challenging light conditions, such as direct sunlight

DETAILS

A unique patented unit in the form of a cylindrical brush, which is directed into the olive tree and orientated between the branches for fruit removal. During the…

Read more

… ‘brushing’ process, the flexible fingers shake in an alternating motion causing the fruit to fall from the branch.

The movement of the brush on this innovative patented fruit removal head can be adjusted based on tree type and collection time, limiting loss of leaves and small branches.

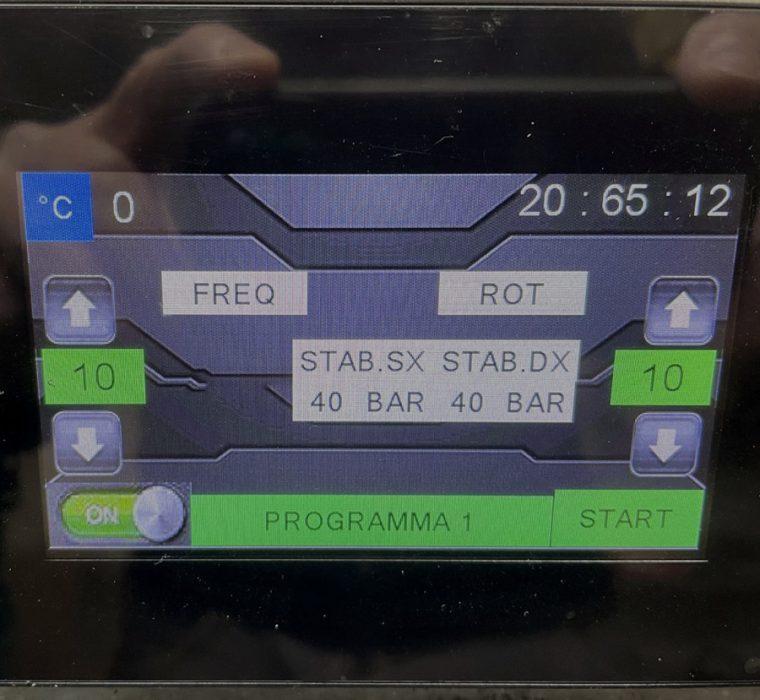

The operator uses a pratical, clear and ergonomical control panel that allows complete control of all the machine’s functions and lets the operator perform even the most difficult manoeuvres safely…

Read more

… and freely.

It’s equipped with joysticks, switches and emergency push button, to move the articulated arm and the unit with flexible fingers between the branches.

Also, to make easier the learning of the use of the machine, on the transmitter, has been inserted a switch for the double speed: slow, the inexpert and fast for the experts.

The large rotating table allows the harvesting arm to work at full extension, even on steep slopes, ensuring complete safety. The rotation is…

Read more

… 360° without a stop in the standard version, while it has a stop in the SMALL version.

The use of a proportional distributor allows the operator to simultaneously control all movements of the mechanical arm’s joints in proportion to the joystick’s displacement. This system facilitates…

Read more

…smooth movements when bringing the brush closer to the branches, preventing jolts, sudden accelerations, or abrupt stops. With this technology, harvesting becomes more precise and gentle, enhancing the overall effectiveness of the operation.

The special structure of the articulated arm with double telescopic arm represents the ideal solution both for the collection of secular olive trees, also remarkable dimension, both of little trees…

Read more

… and also on narrow planting or on terraces.

The machine, applied to tractor 3 point hitch, can work indifferently with long net strips, spread and recovered later by the net motorized Roller system, or with mechanical interceptor umbrella to reduce the number of the workers.

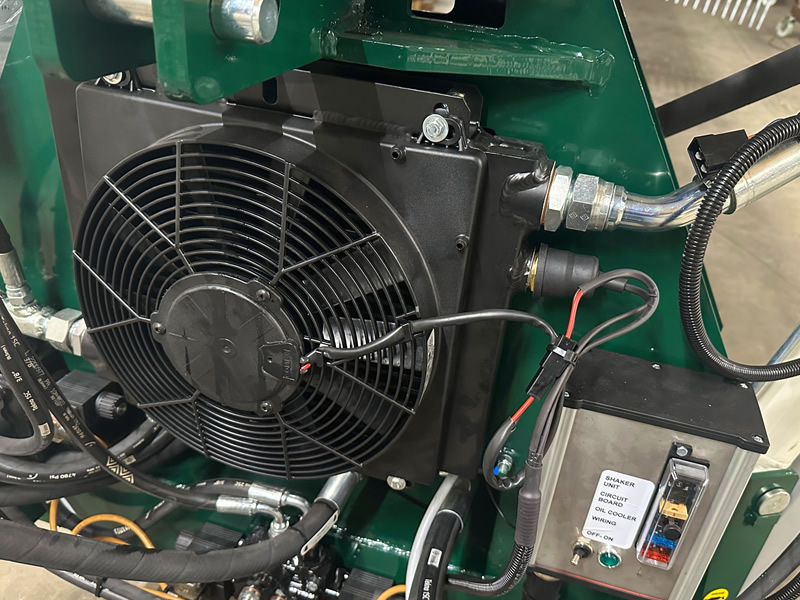

To ensure continuous operation for up to 8 hours without the risk of oil overheating, OLIVE ONE comes standard with a large oil cooler. As the only machine on the market to offer…

Read more

… this solution, it guarantees consistent and safe performance throughout the entire working cycle.

OPTIONAL

SEE HOW IT WORKS